A transfer chute, like any other bulk material handling equipment, needs a few things on the basis of which it has to be designed. The decisive parameter amongst all these is the material that is being handled.

If Iron ore is the material that is being conveyed, the transfer chute needs to be in such a way so that the angle of the discharge leg should be more than angle of repose of Iron ore, which is roughly around 38°. Since Iron ore is highly adhessive and cohessive, the chute needs to be lined with flow improving material, or the cross-section needs to be designed keeping in mind the feed rate(tonnage handle per hour) and belt speed.

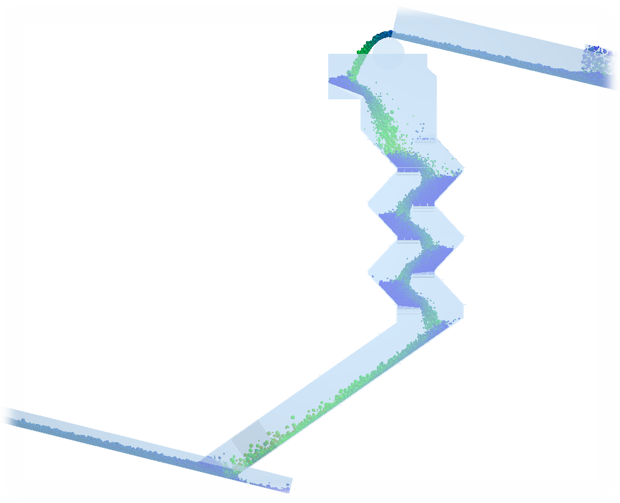

At BMHequip, we follow a set of organised steps to design or redesign a chute; assess the chute for its existing issues at the site, generate a 3d model of the present chute and simulate the material for its behaviour, check for all the conflicting zones inside a chute body, design a new chute with the help of DEM validated simulations, compare the two chutes side by side visually, and finally check for the new chute's structural integrity.

Comentarios